- We work with global industries!

Picture this: your plant's alarms blare falsely because sticky buildup fools the level switch, pumps run dry and burn out, or tanks overflow wasting expensive materials. These headaches from unreliable sensors cost thousands in downtime across chemical plants, silos, and wastewater setups. In the RF admittance level switch vs capacitive level switch debate, one shines for real-world reliability while the other falters under coating and moisture-helping you pick the winner for smooth operations.

Cheap level switches promise savings but deliver endless false alarms, dry-run pump failures, and overflow messes that halt production. Operators waste hours cleaning probes or recalibrating, turning "budget" picks into long-term money pits. RF admittance and capacitive level switches look similar at first glance, but their performance diverges sharply in tough conditions-making the right choice key to uptime.

A level switch detects if material hits a specific point in tanks, silos, hoppers, or sumps, triggering alarms, pumps, or valves for safety and efficiency. Unlike continuous level transmitters that track full ranges, switches focus on high/low points-like overfill protection or empty alerts. They're vital in automation for preventing disasters in food processing, chemicals, or mining.

Capacitive level switches sense material by changes in capacitance between a probe and ground, as liquids or solids alter the electric field. The probe acts like one plate of a capacitor; material presence boosts capacitance to switch on. They suit clean, dry setups like plain water tanks but struggle where coatings form.

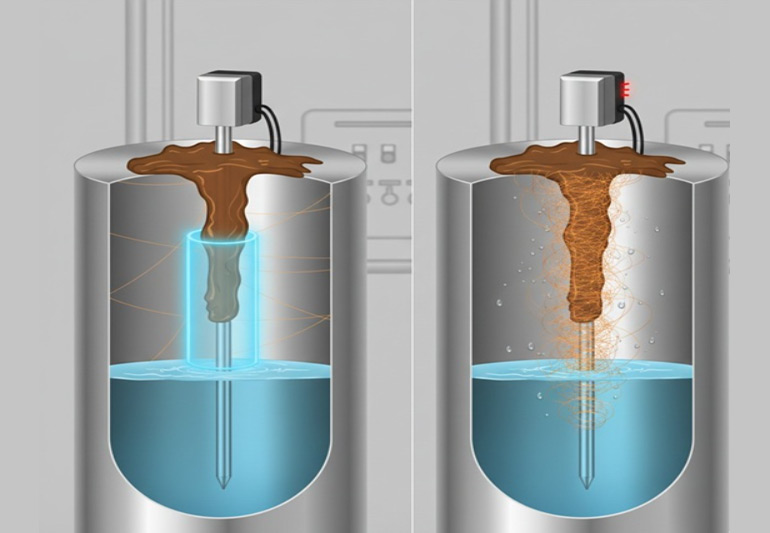

RF admittance level switches build on capacitive tech with radio-frequency signals and an active shield, measuring admittance (capacitance plus conductance) for superior accuracy. The shield wraps the probe, driven at the same voltage to ignore buildup. It focuses on sense-to-earth admittance, excelling with coatings, moisture, or conductive materials like slurries and powders.

It measures total probe-to-earth capacitance; material contact changes the dielectric, tripping the switch. But coatings add fake capacitance, mimicking full levels and causing false highs. Over time, sensitivity drifts from dirt or wear.

A high-frequency RF signal hits the probe and shield equally-no current flows between them, wiping out probe-shield capacitance. Only sense-to-earth changes from true material contact register, shielding against coatings for stable detection in harsh spots.

| Parameter | RF Admittance Level Switch | Capacitive Level Switch |

| Coating Immunity | High (ignores buildup) | Low (false trips) |

| Sticky Materials | Excellent | Poor |

| Conductive Liquids | Reliable | Unstable |

| Humidity/Moisture Sensitivity | Minimal | High |

| False Alarms | Rare | Frequent |

| Maintenance | Low | High |

| Long-Term Reliability | Very High | Moderate |

In wastewater sludge, adhesives, or syrups, capacitive sensors misread coatings as levels, halting lines. RF admittance level switches cut through, detecting true presence for nonstop flow.

Cement, fly ash, or grains bring dust and condensation; capacitive types spark false signals from static or moisture. RF admittance stays steady, grounding charges safely.

Struggling with unreliable sensors?

Check Levtron's Standard RF Admittance Level Switch for proven fixes

Both mount via threads or flanges with simple wiring to PLCs, but RF admittance's compact housing fits tight spaces better, with universal power (15-260 VAC/DC).

Capacitive switches need frequent tweaks as buildup shifts readings. RF admittance calibrates once and holds steady, thanks to coating immunity.

Capacitive downtime from cleaning adds up fast. RF admittance's no-moving-parts design slashes service calls, delivering lower lifetime costs despite upfront price.

For clean, non-coating liquids in low-stakes spots-like basic storage or budget pilots-capacitive level sensors keep things simple and cheap without drama.

Pick RF admittance for coating-prone slurries, conductive media, or critical alarms in chemicals, pharma, or mining. It cuts maintenance and downtime, ideal for plants chasing reliability.

Ready to upgrade? Explore Levtron's RF admittance solutions today

RF Admittance vs Capacitive Level Switch - Final Verdict

RF admittance level switch crushes capacitive in performance, reliability, and cost over time-especially where coatings or harshness rule. Capacitive suits only pristine setups.

Plants now prioritize zero-downtime automation, safety standards like Exd ratings, and harsh-condition compatibility. RF admittance technology meets these with versatile, maintenance-free operation.

Match your switch to the job: capacitive for easy tasks, RF admittance for the rest. Skip short-term savings traps-invest in what lasts.

Discover Levtron's Standard RF Admittance Level Switch for your needs

Is RF admittance better than capacitive level switch?

Yes, for coatings, sticky media, and reliability-capacitive falters there.

Does coating affect capacitive level sensors?

Heavily, causing false readings; RF admittance ignores it.

Can RF admittance level switches work with solids and liquids?

Absolutely, from powders to slurries.

Which level switch requires less maintenance?

RF admittance-no cleaning or recalibration hassles.

Is RF admittance suitable for conductive materials?

Perfect, unlike capacitive sensors.